Snap-On Ultrasonic FlowMeter

Category:

keyword:

Product Overview

The clamp-on type is a kind of clamp-on ultrasonic flow meter product with a one-piece design, which has the characteristics of small volume and simple installation and operation, and is suitable for various small-diameter pipeline liquid medium flow process monitoring applications.

Measurement principle

When a beam of ultrasound is transmitted through a liquid, the flow of the liquid causes a small change in the transmission time, which is directly proportional to the flow rate of the liquid. When the flow rate is zero, the time it takes for the two sensors to emit and receive sound waves is exactly the same (the only technology that can actually measure zero flow), and when the liquid is flowing, the time it takes for the sound wave to travel upstream is greater than the time it takes to travel downstream.

Its relationship conforms to the following expression:

Wherein:

θ is the angle between the sound beam and the direction of liquid flow

M, the number of times the sound beam travels in a straight line in the liquid.

D inner diameter of the pipeline

Tup is the time of sound beam propagation in the positive direction

Tdown is the time for the sound beam to travel in the reverse direction

ΔT=Tup –Tdow product features

Product features

1. The measuring medium does not need to be conductive;

2. The installation process does not require pipe cutting, and there is no need to shut down production. There are no moving parts and no pressure loss;

3. Installation personnel do not need professional training, and can complete the installation according to the installation video or installation steps;

4. Aviation aluminum, stainless steel fixtures, more used in supply control environment.

Product application environment

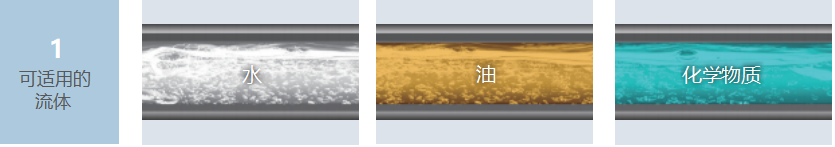

Applicable medium (common examples, if not listed, please contact the factory for confirmation)

The product almost meets different single clean liquid measures:

Main applications in the metering and control of water (tap water, pure water, ultra-pure water).

Technically, due to the continuous promotion of the application industry for various acids, alkalis,

Organic liquids, chemical solvents, alcohol, beverages, etc. are also well applied.

Applicable medium (common examples, if not listed, please contact the factory for confirmation)

The product almost meets different single clean liquid measures:

The main application is in the metering and control of water (tap water, pure water, ultra-pure water), and due to the continuous promotion of application industries, it is also well applied to various acids, alkalis, organic liquids, chemical solvents, alcohol, beverages, etc.

Pipeline material

The product almost meets the measurement of different types of pipes for guiding sound, including both "metal pipes" and "plastic pipes" can be measured.

Through the options of the menu, a flow meter can measure both metal and plastic pipes.

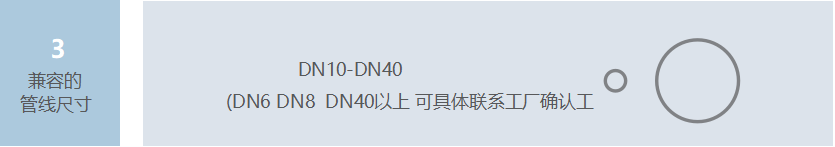

Pipeline scope

Small pipes DN40 below, other equipment measurement data is not accurate, usually this equipment is used for measurement.

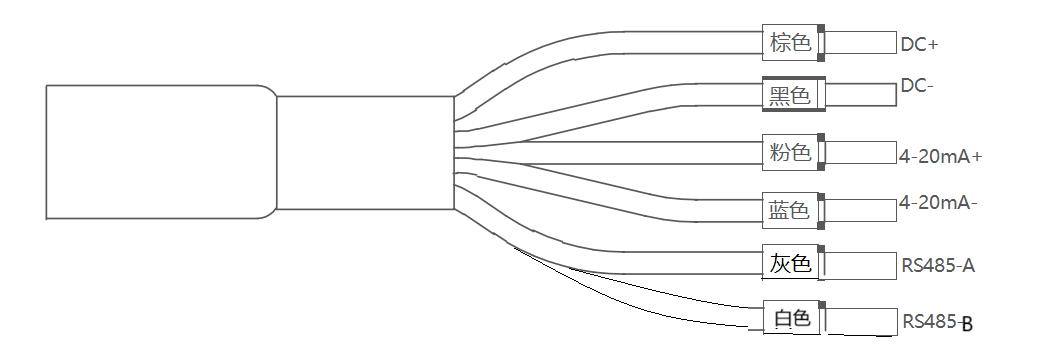

Cable definition

1. Interface type: M16-A type - 6 core

2. Wiring diagram:

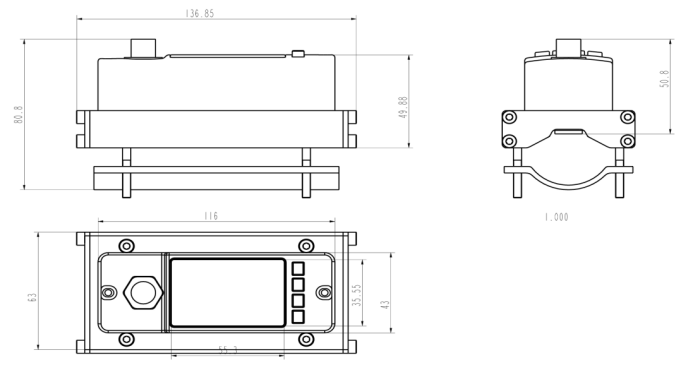

Sensor size

Installation

1. The pipe clamp is first fixed to the pipe and tightened;

2. The sensor is assembled to the pipe clamp and the sensor fixing screws are tightened.

3. Note that the sensor position is selected away from elbows, valves, tees, etc. that affect the flow pattern, and the sensor is installed at a straight pipe position more than 10 times the pipe outer diameter.

|

Case material |

Aluminum alloy; plastic |

|

Install screws |

Stainless steel |

|

Protection level |

IP54 |

|

Flow rate range |

0.05-6m/s ,>0.2m/s meets the accuracy |

|

Calibration medium |

Factory calibrated medium: water |

|

Product specifications |

UTX-10, UTX-20, UTX-32, UTX-50, |

|

Measurement range |

UTX-10: Outside diameter Ф13-18mm UTX-20: Outside diameter Ф18-28mm UTX-32: Outside diameter Ф28-44 mm UTX-50: Outside diameter Ф44-64 mm |

|

Pipeline material |

Stainless steel, carbon steel, copper, PVC, PP, PVDF and other dense pipes |

|

Measuring medium |

Water, alcohol, gasoline, chemical solvents and other fixed composition liquids (without solid particles and impurities) |

|

Medium temperature |

Standard sensor -10℃ - 65℃ (not frozen)/ split sensor -20℃ - 160℃ |

|

Measurement accuracy |

Error < 2% |

|

Response time |

1s – 5s |

|

Power supply |

12-24VDC |

|

Power consumption |

2W |

|

Power/output interface |

M12-A type-6 core, 1 piece |

|

output |

4-20mA |

|

Communication |

RS485 Modbus |

|

Display screen |

12864, LCD (white background, black characters) |

|

Key; |

Touch-sensitive mechanical button, 4 |

|

Working environment temperature |

-10℃ - 60℃ (unfrozen) |

|

Storage temperature |

-10℃ - 60℃ |

Related products

Related products

Welcome to leave a message for consultation

Welcome to leave a message for consultation

Inquiry

Inquiry